Navigation tools and display settings to perform zoom, pan and orbit functions. You can make changes by RC on the operations icon in the timeline, and you can change operation orders by dragging inside the timeline.ħ. Timeline – displays all operations performed in the design. Use left click (LC) to select objects in the canvas and right-click (RC) to access the context menu with frequently used functions.Ħ. Drawing canvas and a context menu (when you right-click the sketch). Design toolbar with active modeling modeĥ. “Good intro to the software! Learned lots of useful tricks and tools through pre-planned projects.2. Provided: PCs with Fusion 360, example files. Please refer to AutoDesk’s website for more details. Many people can continue to use the program for free (as of this writing), including students, startups, hobbyists, and so on. Fusion 360 can be evaluated for free for 30 days by anyone–we will try our hardest to keep this class well under that limit.

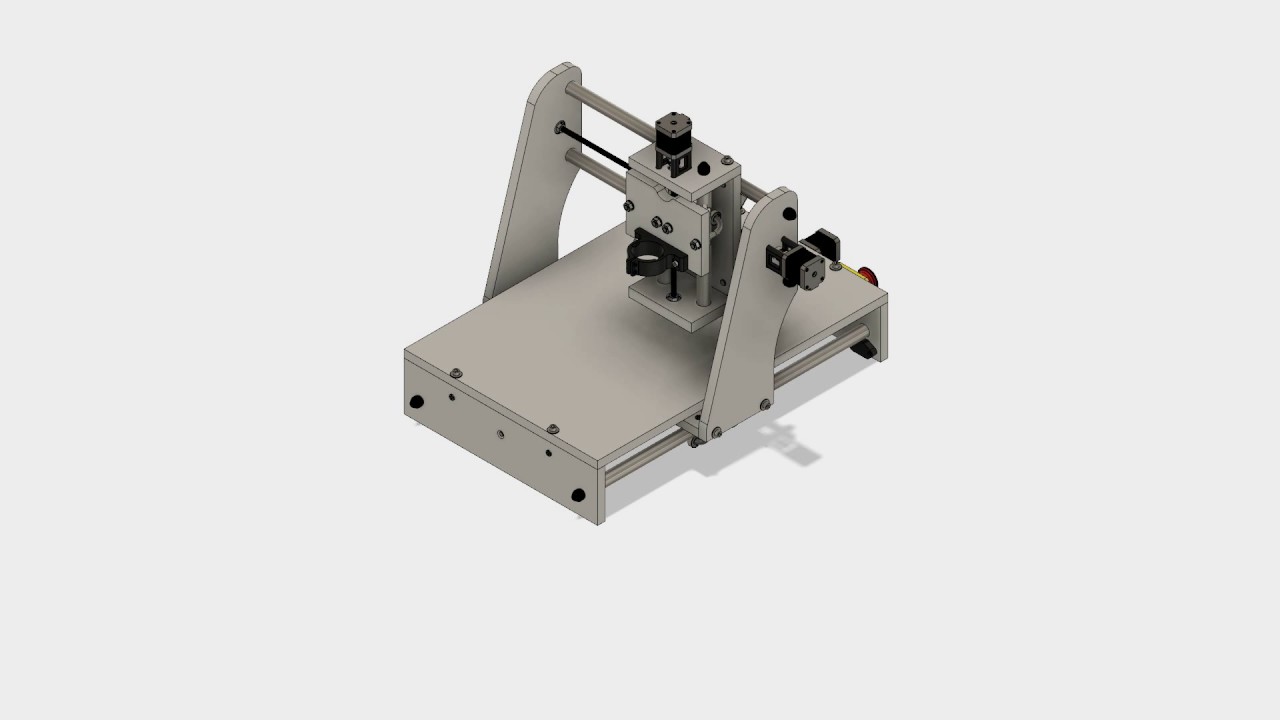

Important: Everyone–including you–will need to establish an account with AutoDesk to use the software. Download the model files here for use in the class. If you wish, you can install Fusion 360 (CAD and CAM are included, along with some other tools) on your own computer, but we will have computers with the software already installed for your use in the class. The amazing capabilities of CNC must be tempered with reality.īring to class: Nothing is required. Just because we can simulate a 1/32″ endmill carving a 1″ deep slot in a block of steel in a single pass doesn’t mean we can make it so in the real world. As we will point out, CAD, CAM, and CNC are not magic, and in general must adhere to the same limitations and guidelines as when manually machining. Not covered in class: We won’t cover machining directly, which is an important thing to keep in mind. However, since CAM is focused on producing tool movements on a physical machine, some basic idea of machining (e.g., a milling machine or router) will provide a needed background. We will be using models created in Fusion 360 (CAD), but it is not an absolute requirement that you have experience with Fusion 360 CAD. Prerequisites: CAM is the intermediate step between CAD (producing a computer model) and a CNC machine (producing a physical model). How it relates with other 2D and 3D CAM programsĪdditional information required for CAM (material, tools, fixtures, etc.) With Fusion 360 CAM, you can generate G-code that runs on the following tools at Maker Works: CAM is the bridge between a CAD model (created in Fusion 360 or another program) and the G-code that runs on the actual CNC machine.

In this class you’ll learn the basics of CAM using Fusion 360.

0 kommentar(er)

0 kommentar(er)